Digital transformation has been altering the way we process and consume information coming from the rig sensors. Gigabytes of real-time log data are being transferred and stored on WITSML servers and are readily available for the end-users. With increased computer and programming capabilities, these data can be utilized for both geosteering and drilling analytics purposes. When it comes to the integration of these areas in one suite, it unveils significant room for advancements in operations. Specifically, our team managed to bring real-time changes of well tops, retrieved from the geosteering model, into an integrated correlation panel continuously adjusting the technological parameters’ forecast for current horizontal well being drilled. A proactive approach helped our client to avoid unplanned operations and complications. In this paper, we are showing the study cases of this integration gained during the combined service for 20 wells in the East Siberian region.

Workflow

Remote geosteering support centres, with a multi-monitor setup, appear either at operator or service company offices. And practice shows that one geosteering specialist can normally handle up to five horizontal wells at a time. This advancement in operations has been decreasing operational cost that convinces more and more companies to transfer their personnel from the rig to the office to perform remote well placement. On the other side, the same emerging trend can be captured for directional drilling services. The market started to suggest a remote directional drilling steering service that allows another circle of cost-cutting. However, because of the traditional academic separation of drillers and geologists, the processes they operate and manage are not fully integrated into each other. As a result, the drilling programs are based on the pre-job geological models and are not being adjusted to geosteering model changes in real-time. Therefore, technological parameters are being applied to the wrong geological conditions with corresponding consequences.

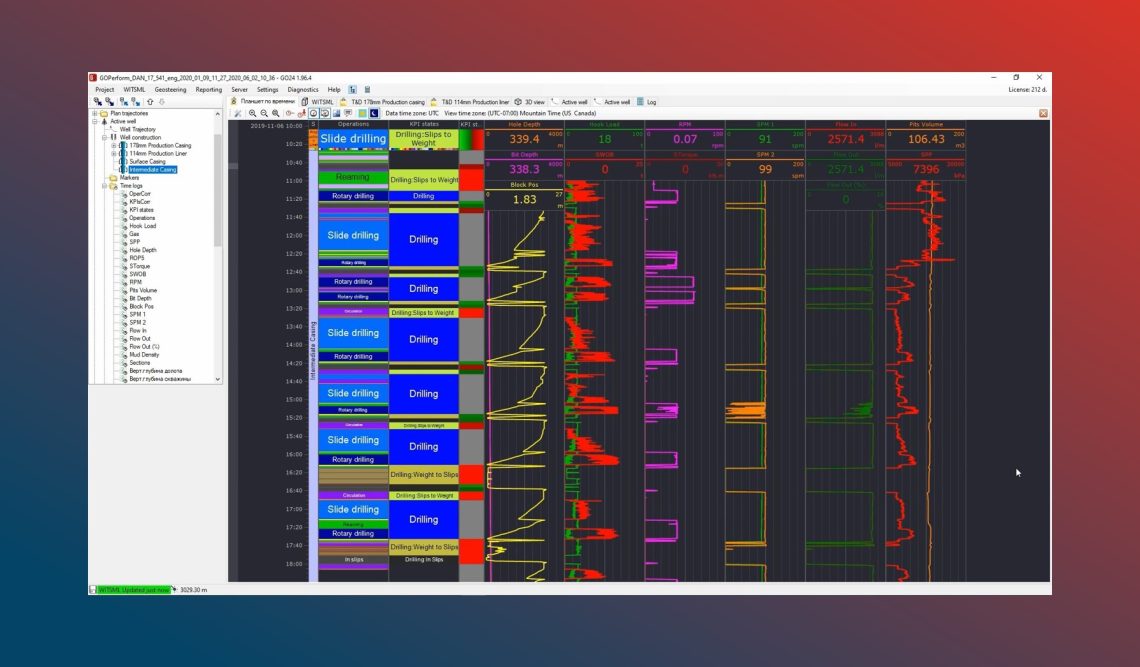

After discussions on client’s needs, our team introduced in 2019 a solution that enables visualization and processing of technological and geological parameters within the same integrated well correlation panel. Once the geosteering model has been changed, new well tops are being transferred via the cloud to the correlation panel to adjust the technological parameters’ forecast for the current horizontal well being drilled.

Integrated well correlation panel

Real-time Gamma Ray and Torque correlation

During Geoconvention 2020, we demonstrated results of one this integration gained over the years combining the service, geosteering, and drilling analytics, for 20 wells in the East Siberian region. Gained experience is equally applicable for high-tier and low-tier projects. Along with geosteering/drilling analytics integration and within the same project, we introduced also automatic drilling operation and KPIs recognition.

Results

Implementing integration of real-time geosteering and drilling analytics helps to address changing geological conditions and results in decreasing NPT. The correlation between both parameters and this technique can be used in a wide variety of operations such as while drilling Viking Formation in Saskatchewan, where Gamma Ray data differences are not clear enough to sustain a geosteer based on that data.